China Multifunctional Servo Riveting Machine

At Pinjialing, we are proud of our commitment to providing high quality servo punching machines. It can meet the high-precision production requirements of precision manufacturing enterprises, such as stamping, forming, riveting, embossing, grease coating, and glue coating. After years of industry accumulation, our equipment has been widely used in motors, power tools, smart homes, auto parts, home appliances, 3C intelligence and new energy industries. Providing operators with a reliable and low-maintenance solution for their service stamping equipment.

Company capabilities

At Pinjialing, we take great pride in our commitment to providing our customers with superior quality servo punching equipment. Our equipment is designed to meet the stringent requirements of precision manufacturing companies in high-precision production processes such as stamping, forming, riveting, grease coating, and glue coating. With years of industry experience and accumulation, our products have been deeply applied to many fields such as motors, power tools, smart homes, auto parts, home appliances, 3C intelligence, and new energy, and have won the trust and praise of our customers. We are committed to providing operators with efficient, stable and low-maintenance servo stamping equipment solutions to help customers improve production efficiency, reduce operating costs and achieve sustainable development.

The company’s main products and equipment

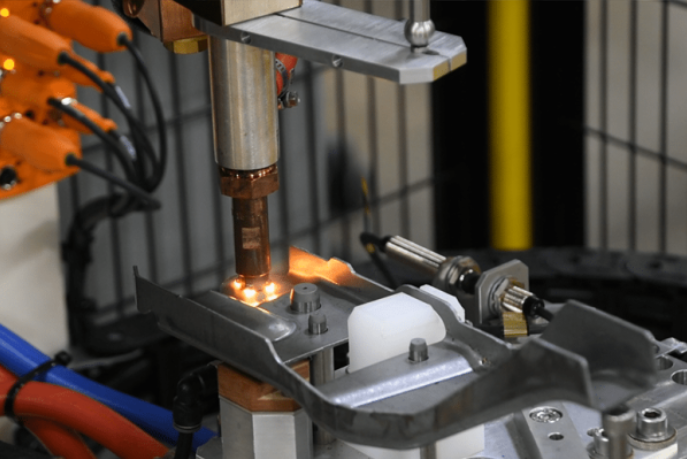

Our multi-functional servo riveting machine uses advanced servo technology to achieve high-precision positioning and stable operation during the riveting process through a precise control system. Whether it is small precision parts or large structural parts, this equipment can easily handle and meet various riveting requirements. At the same time, the servo riveting machine also has a variety of riveting modes, including spot riveting, continuous riveting, etc., which can be flexibly adjusted according to specific process requirements.

Work Efficiency

Multi-functional servo riveting machines offer significant advantages. Its high-speed riveting speed and stable riveting quality greatly improve production efficiency and reduce labor costs. In addition, the equipment also has functions such as automatic feeding, automatic positioning, and automatic detection, which realize automatic operation of the whole process, reduce human intervention, and improve the stability and reliability of the production line.

Quality assurance

The multi-functional servo riveting machine also performs well. With a precise control system and high-quality riveting dies, the equipment can ensure the accuracy and consistency of each riveting point, avoiding errors and defective products that may occur in traditional manual riveting. The equipment also has complete fault detection and alarm functions. Once an abnormality is detected, it can shut down and issue an alarm in time to ensure production safety.

Maintenance and support

Pinjialing is your trustworthy partner, committed to providing operators with efficient, stable and low-maintenance servo stamping equipment solutions by providing high quality equipment and excellent support, helping customers improve production efficiency, reduce operating costs and achieve sustainable development. If you are interested in our innovative products and quality services, please contact us for more information.

يتم تحديث الأسئلة الشائعة بانتظام لتعكس أحدث المعلومات ولضمان حصولك على التفاصيل الأكثر دقة في متناول يدك.

نشكرك على اختيارنا، ونأمل أن تجد الإجابات التي تحتاجها!

- Is it easy to use?

Yes, it’s easy to use. Just pour cream into the machine, turn it on and let it do the churning for you.

- What is Motorcycle engine cradle servo press?

Manual auxiliary loading and unloading of the cradle, automatic loading of the bushing, automatic installation of the pivot tube rubber sleeve, and automatic pressure installation of the bushing.

The equipment mainly consists of: casting frame, automatic loading and unloading system, multi-station turntable, servo pressing system, human-computer interaction system, safety protection system and other parts.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.

- Which shipping way can you provide?

We can provide shipping by sea, by air, by express and etc according to customer requirements.

- What is the use of Servo Riveting Machine?

Guangdong Pinjialing Intelligent Technology Co. Ltd. is a professional servo press, precision coating and related equipment R & D and manufacturing as one of the modern technology-based enterprises. Our servo riveting machine is used to automatically set (press) rivets to join materials together. The riveting machine offers greater consistency, productivity and lower cost compared to manual riveting.

- Why should I buy from your company not from other suppliers?

As a technology company, Pinjialing’s products have its own core technologies and patents. And has certain influence and popularity in the peer field. We have our own software engineering development department, expert engineering design department, precise production process, strict QC management and high-quality after-sales service.

- Who are we?

Our headquarters is located in Guangdong, China, and sells to Southeast Asia, Eastern Europe, Western Europe, North America, Northern Europe, Central America, South America, East Asia, South Asia, Oceania, Southern Europe, Africa, and the Middle East.

- What is a Desktop Servo Riveting Machine?

Desktop Servo Riveting Machine are high-torque machines. They are able to produce the output pressing force with full energy at any point of an operation.

- What is Servo Riveting Machine?

Our servo riveting machine is a kind of automated equipment used for the process of riveting. Riveting is a permanent fastening method that joins two or more materials together using a rivet, which is a metal pin with a head at one end. The rivet is inserted into pre-drilled holes in the materials to be joined, and then the other end is deformed or “headed” to secure the materials in place.

- What are the advantages of using a servo press machine?

The advantages of using a servo press machine include reduced production costs, increased productivity, improved product quality, and better energy efficiency.