中国リニアアクチュエータプレス

Introduction

Welcome to the world of Pinjialing, a modern technology leader integrating servo stamping, precision painting and related equipment R&D and manufacturing. Pinjialing takes technological innovation as the guide, quality first as the cornerstone, and quality service as the commitment. We understand the unique needs of each customer and are committed to developing customized precision servo presses and precision coating equipment, while also creating various non-standard automated production lines to meet the diversified needs of the market. We firmly believe that only through continuous innovation and pursuit of excellence can we provide customers with the highest quality products and services and create a better future together.

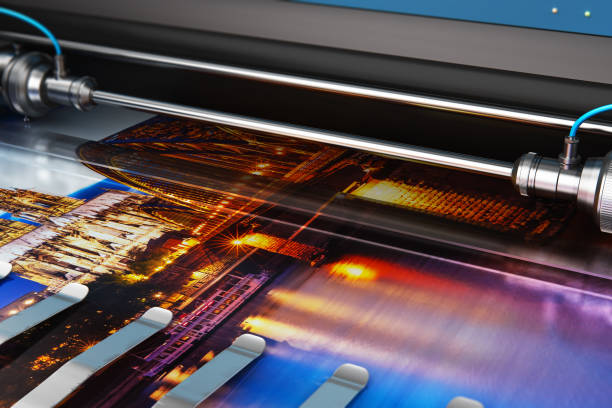

The linear actuator press is an efficient, precise and versatile mechanical device that plays a key role in industrial manufacturing. This press uses advanced linear actuator technology to achieve high-speed and smooth stamping action through a precise control system, ensuring the stability and accuracy of the processing process.

The linear actuator press has a powerful pressure output capability and can meet the stamping requirements of various complex materials. At the same time, its high-precision positioning system and fast response speed make it excellent for handling delicate parts. In addition, the equipment also has a high level of automation and intelligence, and can easily achieve seamless connection with other equipment in the production line to improve production efficiency.

Linear actuator presses also excel in terms of safety. It is equipped with multiple safety measures, such as overload protection, emergency stop, etc., to ensure the safety of personnel during operation. At the same time, its rugged and durable structure and high-quality components also ensure long-term stable operation of the equipment.

The linear actuator press is an excellent industrial equipment that integrates high efficiency, precision and safety. It can strongly support the company’s production and help the company achieve higher production efficiency and lower operation cost.

Excellent service

We always adhere to the concept of excellent service and provide customers with meticulous service. We know that high-quality service is not only an extension of our products, but also the key to winning customer trust and satisfaction. We always adhere to the principle of “customer first” and provide professional, meticulous, and efficient services to protect our customers’ production operations, so that every customer can feel our dedication and professionalism.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is Servo Riveting Machine?

Our servo riveting machine is a kind of automated equipment used for the process of riveting. Riveting is a permanent fastening method that joins two or more materials together using a rivet, which is a metal pin with a head at one end. The rivet is inserted into pre-drilled holes in the materials to be joined, and then the other end is deformed or “headed” to secure the materials in place.

- How is a servo press machine different from a mechanical press machine?

A servo press machine differs from a mechanical press machine in that it employs a servo motor that provides precise control over the ram’s position and speed, while a mechanical press machine uses a flywheel and clutch to control the ram.

- What is the maintenance required for a servo press machine?

A servo press machine requires regular maintenance, including lubrication, checking for wear of components, and calibration of the servo motor. Regular maintenance ensures optimal performance and longevity of the machine.

- How to place order?

When you are ready to order, please contact us for confirm the suitable solution & plan & model. What cannot be ignored is you should provide a copy purchase order to ensure that your order is processed properly.

- Is there any warranty after purchasing the servo press?

We have more than 13 years of professional manufacturing experience. We provide 2 years warranty for our servo presses. Technical support is provided free of charge forever.

- What is a servo press machine?

A servo press machine is a type of press machine that uses a servo motor to drive the ram. It provides precise control over the stroke and speed of the ram, allowing for accurate and repeatable forming processes.

- Is it safe to use?

Yes, the Electric Butter Machine is safe when used according to the manufacturer’s instructions. Always follow the safety guidelines and precautions outlined in the instruction manual.

- How does an electric churn work?

The Electric Butter Machine has a motorized churn that rotates and agitates the cream, causing the fat globules to coalesce and separate from the buttermilk, resulting in fresh butter.

- What safety precautions should I follow when operating a servo press machine?

When operating a servo press machine, it is important to follow all safety protocols, including wearing appropriate personal protective equipment, using safety guards and devices, and obtaining proper training on the machine’s operation. Additionally, only trained and authorized personnel should operate the machine.

- Who are we?

Our headquarters is located in Guangdong, China, and sells to Southeast Asia, Eastern Europe, Western Europe, North America, Northern Europe, Central America, South America, East Asia, South Asia, Oceania, Southern Europe, Africa, and the Middle East.