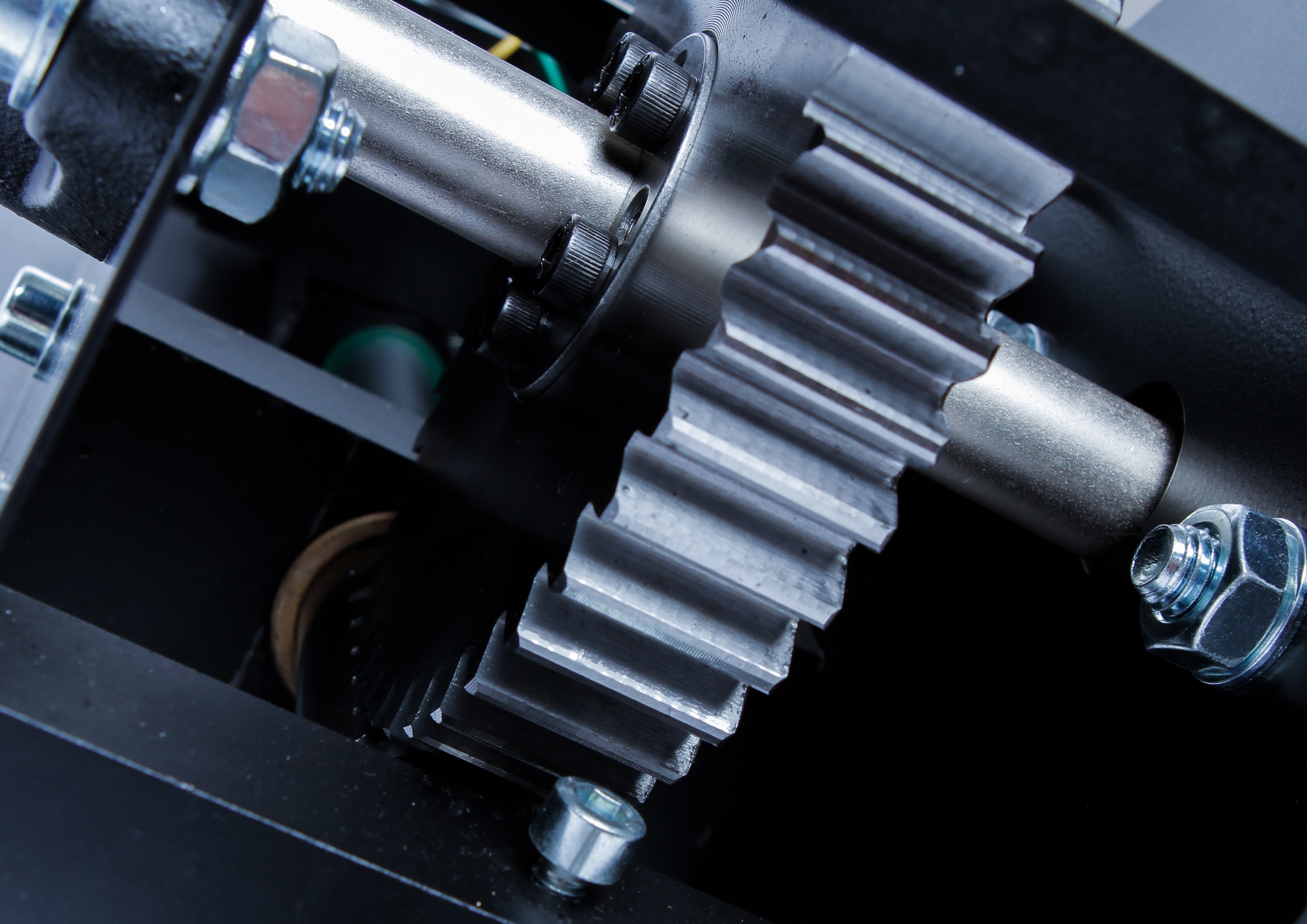

China servo precision leveling machine

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.

- What are the advantages of servo presses in forging?

In addition to making it possible to form materials traditionally considered difficult to machine, our servo presses offer a number of other benefits, including higher forming accuracy, increased productivity, reduced noise, and improved energy savings.

- What safety precautions should I follow when operating a servo press machine?

When operating a servo press machine, it is important to follow all safety protocols, including wearing appropriate personal protective equipment, using safety guards and devices, and obtaining proper training on the machine’s operation. Additionally, only trained and authorized personnel should operate the machine.

- Is it easy to use?

Yes, it’s easy to use. Just pour cream into the machine, turn it on and let it do the churning for you.

- Do you have an inspection procedure for the product?

Yes, We have a strict inspection of product quality and packing.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.

- Why should I buy from your company not from other suppliers?

As a technology company, Pinjialing’s products have its own core technologies and patents. And has certain influence and popularity in the peer field. We have our own software engineering development department, expert engineering design department, precise production process, strict QC management and high-quality after-sales service.

- What types of materials can be formed using a servo press machine?

A servo press machine can be used to form a variety of materials, including steel, aluminium, copper, and other alloys.

- What is the accuracy of the servo press?

Positioning accuracy: (mm) : ±0.01

Pressure Accuracy (%F.S): 0.5

Displacement resolution (mm) : 0.001

- What are the advantages of using a servo press machine?

The advantages of using a servo press machine include reduced production costs, increased productivity, improved product quality, and better energy efficiency.