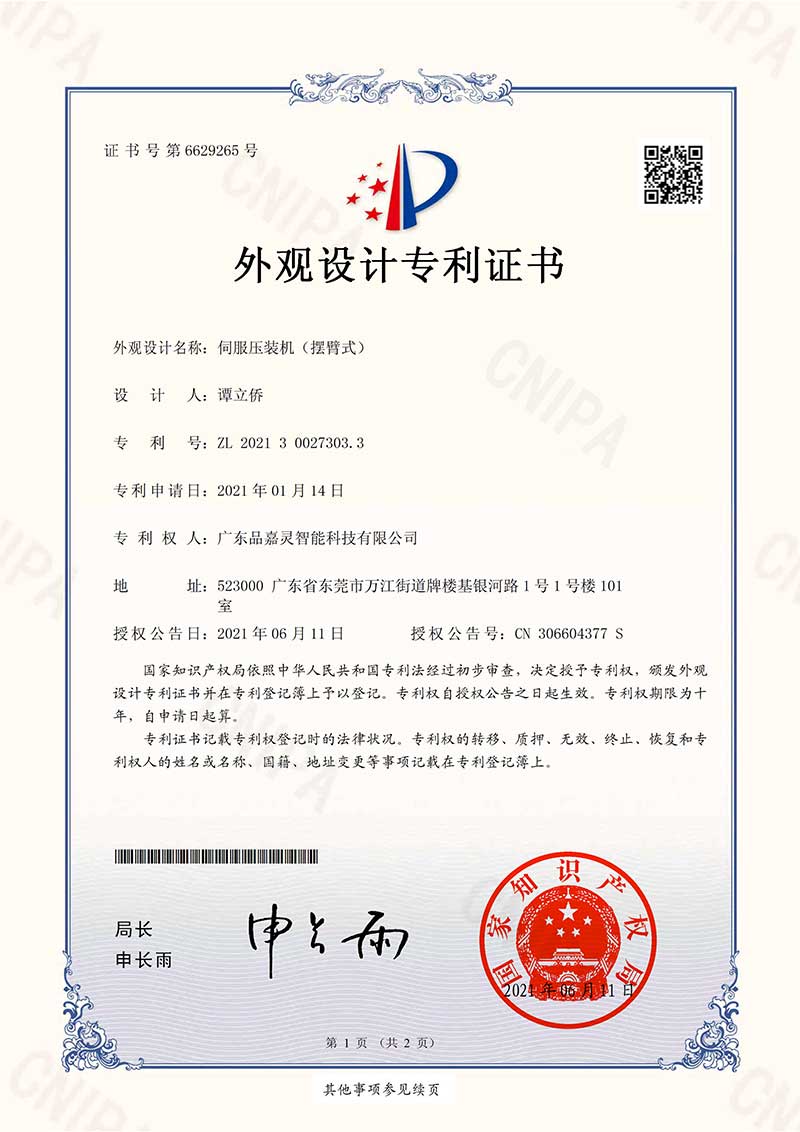

C type servo press machine

Main technical parameters

| 모델 | PJL-C/5KN-100mm/150V | PJL-C/10KN-100mm/100V | PJL-C/20KN-100mm/125V |

| Maximum pressure (T) | 5 | 10 | 15 |

| Effective stroke(mm) | 100( customizable) | 100( customizable) | 100( customizable) |

| Force resolution (%) | 0.005 | 0.005 | 0.005 |

| Displacement resolution (mm) | 0.001 | 0.001 | 0.001 |

| Weight about (KG) | 200 | 260 | 280 |

| Maximum speed(mm/s) | 150 (customizable) | 100 (customizable) | 125 (customizable) |

| Pressing speed (mm/s) | 0.01-35 | 0.01-35 | 0.01-35 |

| Pressure Range(KN) | 25N-5KN | 25N-10KN | 100N-20KN |

| Holding time (s) | 0.1-200 | 0.1-200 | 0.1-200 |

| Positioning accuracy (mm) | ±0.01 | ±0.01 | ±0.01 |

| Pressure Accuracy (%F.S) | 0.5 | 0.5 | 0.5 |

| Closed mold height (mm) | 300 | 300 | 300 |

| Throat depth(mm) | 120 | 120 | 120 |

| L*W*H(mm) | 580×560×1900 | 545×635×2100 | 545×536×2100 |

| For 3T and above, it is recommended to choose a four-column structure | |||

C-type servo press machine is a type of mechanical press that utilizes a servo motor as its driving force. This type of press is commonly used in various industries for forming, stamping, and cutting operations on sheet metal and other materials.

Equipment features

- High equipment accuracy: repetitive positioning accuracy ± 0.01mm, pressure accuracy 0.5% FS

- The software is self-developed and easy to maintain.

- Various pressing modes: optional pressure control and position control.

- The system adopts a touch screen integrated controller, which can edit and save 10 sets of formula program schemes, display the current displacement-pressure curve in real time, and record 50 pieces of press-fitting result data online. After more than 50 pieces of data are stored, the old data will be automatically overwritten (note: the data will be automatically cleared after power failure). The equipment can expand and insert an external USB flash disk (within 8G, FA32 format) to save historical data. The data format is xx.xlsx

- The software has the envelope function, which can set the product load range or displacement range according to the requirements. If the real-time data is not within the range, the equipment will alarm automatically.

- The equipment is equipped with safety grating to ensure the safety of operators.

- Realize accurate displacement and pressure control without hard limit and relying on precision tooling.

- Online assembly quality management technology can detect defective products in real time.

- According to the specific product requirements, specify the optimal pressing process.

- Specific, complete and accurate operation process recording and analysis functions.

- It can realize multi-purpose, flexible wiring and remote equipment management.

- Multiple data formats are exported, EXCEL, WORD, and data can be easily imported into SPC and other data analysis systems.

- Self-diagnosis and energy failure: in case of equipment failure, the servo press-fitting function displays error information and prompts for solutions, which is convenient to find and solve the problem quickly.

- Multi-functional I/O communication interface: through this interface, communication with external devices can be realized, which is convenient for full automation integration.

- The software sets multiple permission setting functions, such as administrator, operator and other permissions.

Applications

- Precision press fitting of automobile engine, transmission shaft, steering gear and other parts

- Precision press-fitting of electronic products

- Precision press fitting of core components of imaging technology

- Application of precision press fitting of motor bearing

- Precision pressure detection such as spring performance test

- Automatic assembly line application

- Press-fitting application of aerospace core components

- Assembly and assembly of medical and electric tools

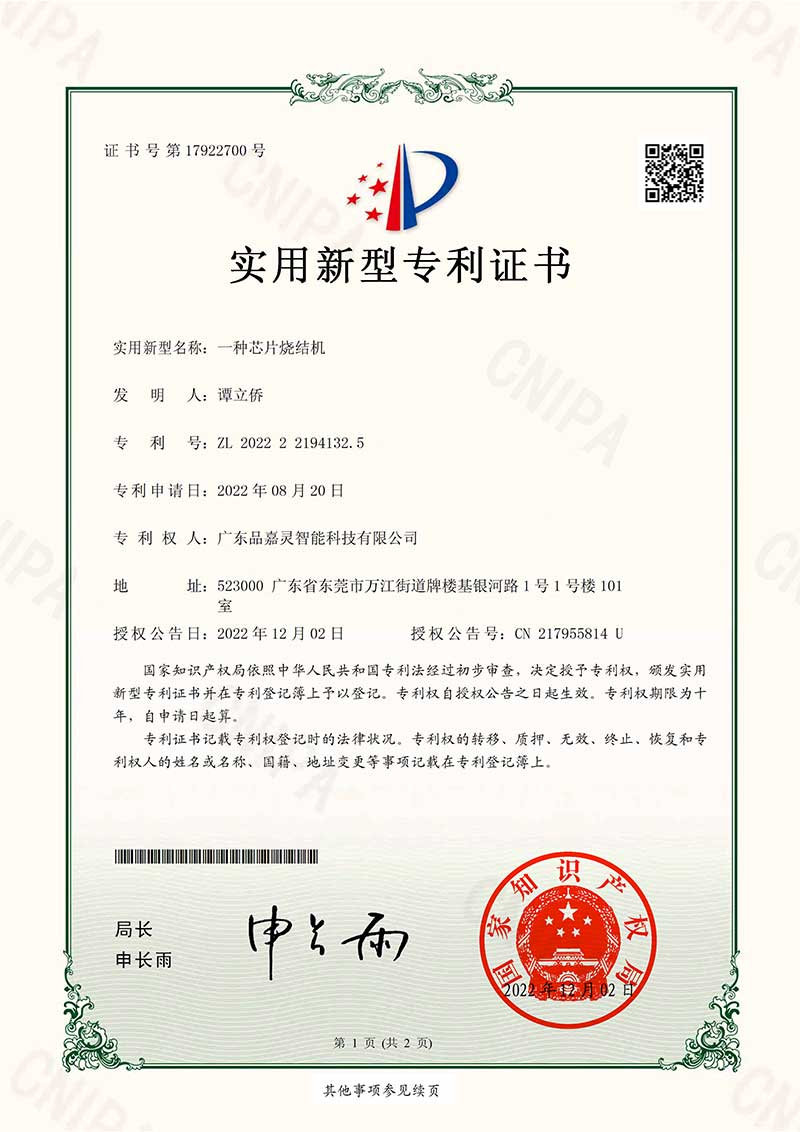

We have obtained various international management system certifications and comply with production standards in different regions.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is a Desktop Servo Riveting Machine?

- What are the advantages of servo presses in forging?

- Is there any warranty after purchasing the servo press?

- What is the accuracy of the servo press?

- What is a servo press machine?