China Multifunctionele servo-klinkmachine leveranciers

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- How do I select the right servo press machine for my application?

When selecting a servo press machine, it is important to consider factors such as the required forming force and stroke, the material to be formed, and the required production volume. Consult with a reputable supplier to ensure that the machine meets your needs and requirements.

- What is an electric butcher?

An electric butcher, also known as an electric butter churn or butter maker, is a modern device designed to automate the process of churning cream into butter. Churning is the traditional method of turning cream into butter by stirring the cream until the fat globules coalesce and separate from the buttermilk.

- Who are we?

Our headquarters is located in Guangdong, China, and sells to Southeast Asia, Eastern Europe, Western Europe, North America, Northern Europe, Central America, South America, East Asia, South Asia, Oceania, Southern Europe, Africa, and the Middle East.

- What is the accuracy of the servo press?

Positioning accuracy: (mm) : ±0.01

Pressure Accuracy (%F.S): 0.5

Displacement resolution (mm) : 0.001

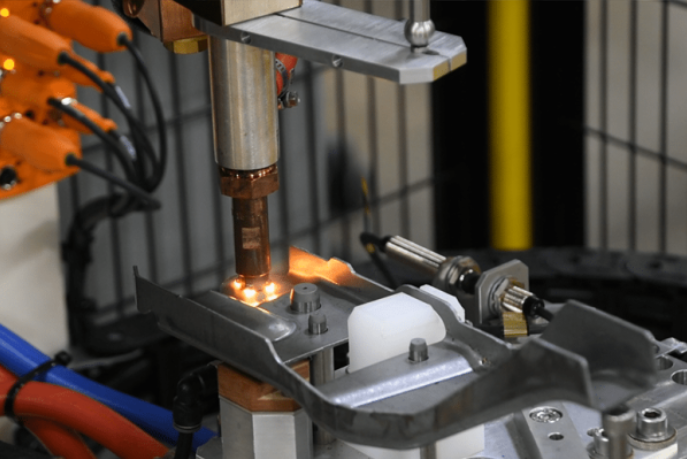

- What is Motorcycle engine cradle servo press?

Manual auxiliary loading and unloading of the cradle, automatic loading of the bushing, automatic installation of the pivot tube rubber sleeve, and automatic pressure installation of the bushing.

The equipment mainly consists of: casting frame, automatic loading and unloading system, multi-station turntable, servo pressing system, human-computer interaction system, safety protection system and other parts.

- What safety precautions should I follow when operating a servo press machine?

When operating a servo press machine, it is important to follow all safety protocols, including wearing appropriate personal protective equipment, using safety guards and devices, and obtaining proper training on the machine’s operation. Additionally, only trained and authorized personnel should operate the machine.

- Is the machine easy to clean?

Yes, most electric butter churners are designed with easy to clean parts. Simply disassemble, wash with warm soapy water, rinse and allow to dry.

- What is the maintenance required for a servo press machine?

A servo press machine requires regular maintenance, including lubrication, checking for wear of components, and calibration of the servo motor. Regular maintenance ensures optimal performance and longevity of the machine.

- How does an electric churn work?

The Electric Butter Machine has a motorized churn that rotates and agitates the cream, causing the fat globules to coalesce and separate from the buttermilk, resulting in fresh butter.

- What is a servo press machine?

A servo press machine is a type of press machine that uses a servo motor to drive the ram. It provides precise control over the stroke and speed of the ram, allowing for accurate and repeatable forming processes.