Tabletop C type servo press machine

Main technical parameters

| модель | PJL-S-0.5T/1T/2T | Weight(KG) | 80 |

| Maximum pressure (T) | 0.5/1/2 | Maximum speed(mm/s) | 150 |

| Effective stroke(mm) | 100-150( customizable) | Pressing speed (mm/s) | 0.01-35 |

| Closed mold height (mm) | 350 | Holding time (s) | 0.1-200 |

| Throat depth(mm) | 120 | Positioning accuracy (mm) | ±0.01 |

| Force resolution (%) | 0.005 | Pressure Accuracy (%F.S) | 0.5 |

| Displacement resolution (mm) | 0.001 | Dimensions (mm) | 570*482*997 |

A servo press machine is a type of press machine used in manufacturing and metalworking industries. It is a more advanced and precise version of the traditional mechanical press. The primary difference between a conventional mechanical press and a servo press lies in the way they control the motion and force during the pressing operation.

In a mechanical press, the motion and force are controlled by mechanical linkages, which can lead to limitations in terms of speed, precision, and adjustability. On the other hand, a servo press utilizes a servo motor (an electric motor with precise control capabilities) to control the motion and force applied during the press operation. This allows for greater flexibility, accuracy, and repeatability in the manufacturing process.

Advantages

1. The equipment has high precision, high efficiency, energy saving and environmental protection.

2. Various pressing modes: pressure control, position control and multi-stage control are optional.

3. The software collects, analyzes, records and saves the pressing data in real time, and the data collection frequency is as high as 1000 times per second. The control board of the press-fit system is connected to the host computer, data storage and upload are faster and more convenient, and the product press-fit data can be traced, which meets the requirements of ISO9001, TS16949 and other standards.

4. The software has an envelope function, and the product load range or displacement range can be set according to requirements. If the real-time data is not within the range, the equipment will automatically alarm, 100% identify defective products in real time, and realize online quality control.

5. The equipment is equipped with a computer host, Windows operating system, and the operation interface of the press-fitting control system can be freely switched between Chinese and English.

6. According to specific product requirements, designate the optimal press-fitting process.

7. It has complete and accurate operation process recording and analysis functions. (The curve has the functions of zooming in, traversing, etc.)

8. Multiple data formats can export EXCEL and WORD data, which can be easily imported into data analysis systems such as SPC.

9. Self-diagnosis function: When the equipment fails, the servo press can display error information and prompt the solution, so that it is convenient to quickly find out the problem and solve it.

10. Multifunctional I/O communication interface: through this interface, it can communicate with external equipment, which is convenient for the integration of full automation.

Working principle of servo press

Pinjialing servo press machine is driven by AC servo motor, through high-precision ball screw to change the rotation force to the vertical direction, relying on the pressure sensor mounted on the front end of the driving part to manage the pressure, and relying on the encoder to control the speed and position. A device that applies pressure to the work object at the same time to achieve the purpose of processing. Can control pressure, stop position, drive speed, stop time at any time. It can realize the whole-process closed-loop control of press-fitting force and press-in depth in the press-fitting operation. The whole press-fitting process is divided into five stages: fast forward, detection, press-fitting, pressure-holding, and return.

Advantages of servo press machines include

Precision

Adjustable Stroke

Programmability

Energy Efficiency

Reduced Noise

Safety

Lower Maintenance

Increased Productivity

Applications

- Precision press fitting of automobile engine, transmission shaft, steering gear and other parts

- Precision press-fitting of electronic products

- Precision press fitting of core components of imaging technology

- Application of precision press fitting of motor bearing

- Precision pressure detection such as spring performance test

- Automatic assembly line application

- Press-fitting application of aerospace core components

- Assembly and assembly of medical and electric tools

- Other occasions requiring precision pressure assembly

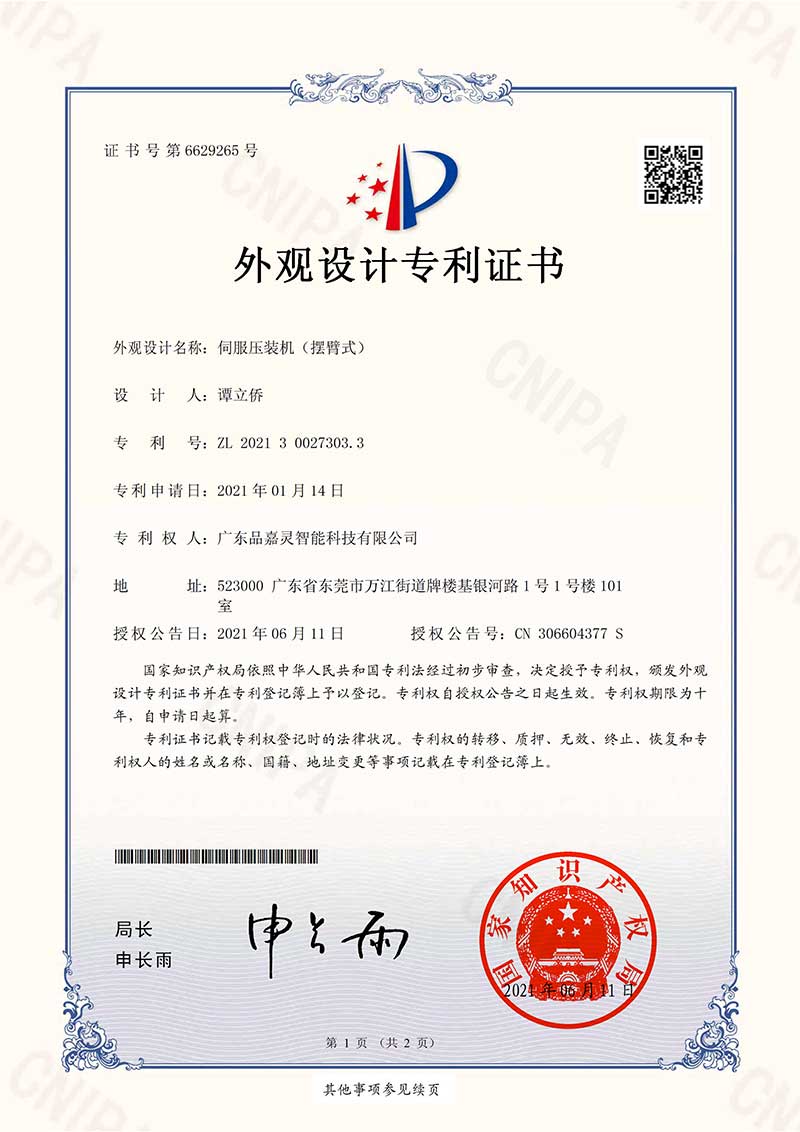

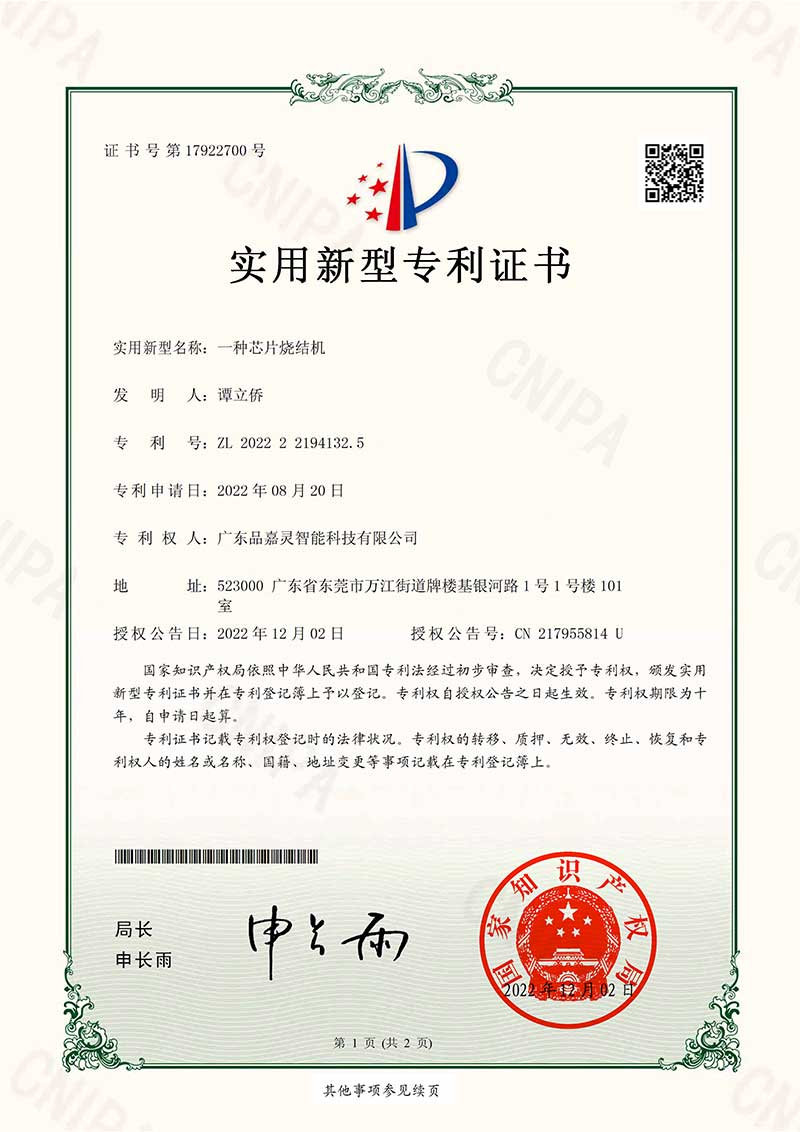

We have obtained various international management system certifications and comply with production standards in different regions.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is a Desktop Servo Riveting Machine?

- What are the advantages of servo presses in forging?

- Is there any warranty after purchasing the servo press?

- What is the accuracy of the servo press?

- What is a servo press machine?