Multifunctional servo riveting machine

Main technical parameters

| technical indicators | PJL-BM0.5T | PJL-BM1T | PJL-BM2T | PJL-JM2T | PJL-BM3T | PJL-BM5T | PJL-BM10T |

| Riveting capacity (mm) | Ø2- Ø6 | Ø2- Ø9 | Ø2- Ø12 | Ø2- Ø6 | Ø2- Ø16 | Ø2- Ø20 | Ø2- Ø30 |

| Maximum spin riveting pressure (N) | 5000 | 10000 | 20000 | 20000 | 30000 | 50000 | 100000 |

| Maximum working stroke(mm) | 100 | 100 | 150 | 100 | 100 | 100 | 100 |

| Closed height(mm) | 250 | 250 | 220 | 220 | 250 | 250 | 250 |

| Throat depth(mm) | 110 | 110 | 150 | 150 | 150 | 150 | 150 |

| Protrusion length of rivet head(mm) | 50 | 50 | 50 | 45 | 50 | 50 | 50 |

| Table size(mm) | 300X200 | 300X200 | 500X300 | 500X300 | 500X300 | 500X300 | 500X300 |

| using electric | AC220 | AC220 | AC380 | AC380 | AC380 | AC380 | AC380 |

| Power Consumption (W) | 1500 | 2000 | 3200 | 3200 | 7300 | 9900 | 11900 |

| motor steering | clockwise | clockwise | clockwise | clockwise | clockwise | clockwise | clockwise |

| Note: The riveting capacity is based on solid Q235 (A3) steel. If the rivet material is non-ferrous metal, hollow nail, the riveting capacity can be enlarged as appropriate | |||||||

|

A multifunctional servo riveting machine is a versatile industrial tool designed to perform riveting operations with the assistance of a servo motor. Riveting is a process used to join or fasten materials together by deforming and compressing a metal pin or rivet. These machines are commonly used in manufacturing, automotive, aerospace, and other industries where strong and reliable fastening is required.

Applications

Automotive Industry

Aerospace Industry

Electronics and Electrical

Metal Fabrication

Construction Industry

Renewable Energy

Medical Devices

Furniture Manufacturing

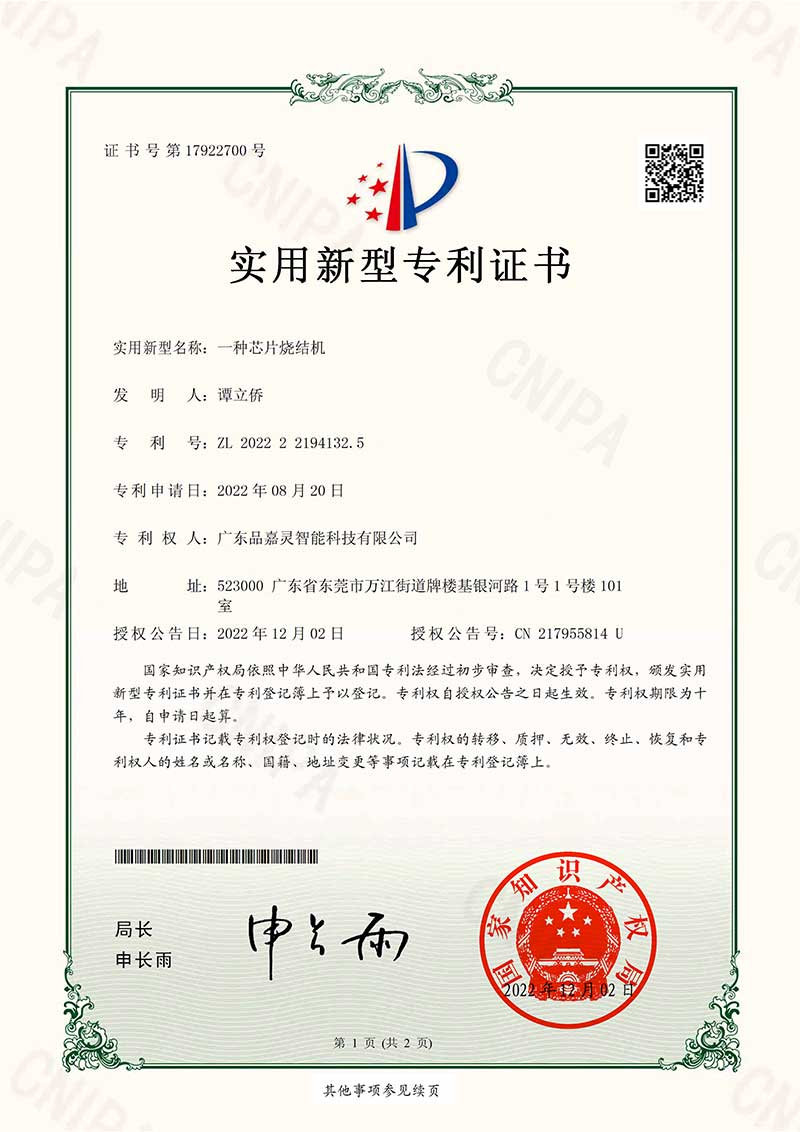

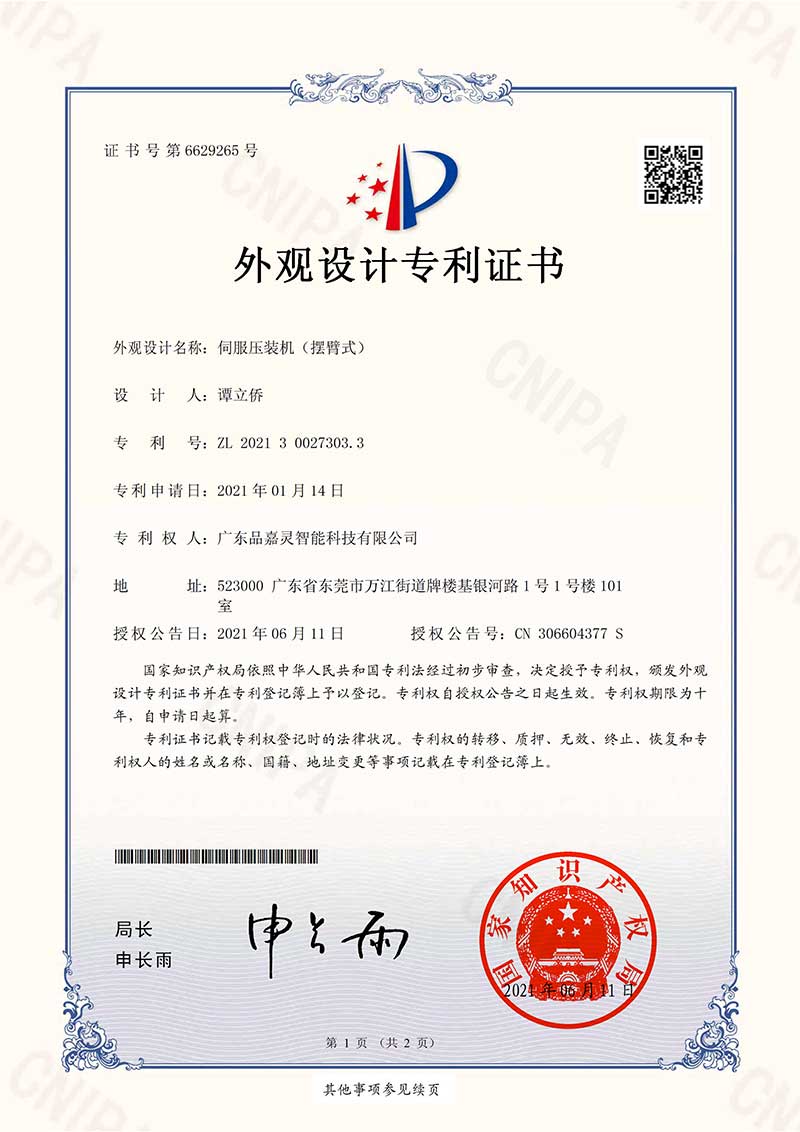

لقد حصلنا على العديد من شهادات نظام الإدارة الدولية ونلتزم بمعايير الإنتاج في مناطق مختلفة.

يتم تحديث الأسئلة الشائعة بانتظام لتعكس أحدث المعلومات ولضمان حصولك على التفاصيل الأكثر دقة في متناول يدك.

نشكرك على اختيارنا، ونأمل أن تجد الإجابات التي تحتاجها!