We always work as a tangible team to ensure that we can provide you with the best quality and the best price for .We sincerely welcome friends from all over the world to cooperate with us on the basis of long-term mutual benefits. The product will supply to all over the world, such as Europe, America, Australia, Dominica ,Algeria ,Philadelphia ,Being the top solutions of our factory, our solutions series have been tested and won us experienced authority certifications. For additional parameters and item list details, please click the button to acquire additional nformation.

Equipment mechanical structure

1)The main body of the equipment: a four-column structure frame, the workbench is machined from a solid plate (ductile cast iron); the body guardrails are made of PC boards, which can safely observe the pressing process, and the machine base is made of casting and sheet metal; carbon steel Parts are treated with hard chromium plating, oil coating and other anti-rust treatments.

2) Fuselage structure: It adopts a four-column structure, which is simple and reliable, has strong load-bearing capacity and small load-bearing deformation. It is one of the most stable and widely used fuselage mechanisms.

Equipment specifications and main technical parameters

| Device name | Intelligent servo press machine |

| Device model | PJL-S-50kN |

| positioning accuracy | ±0.008mm |

| Pressure detection accuracy | 0.5%F.S |

| greatest pressure | 50kN |

| pressure range | 50N-50kN |

| Displacement resolution | 0.001mm |

| Data collection frequency | 1000 times per second |

| program | Can store more than 1,000 sets |

| Valid itinerary | 250mm |

| closed height | 400mm |

| Throat depth | 250mm |

| Indenter mold size | 内径Φ20mm,深25mm |

| Work surface size | 425mm*486mm |

| Distance from work surface to floor | 900mm |

| Equipment dimensions (MM) (subject to production drawings) | 600mm*650mm*2550mm |

| Pressing speed | 0.01-35mm/s |

| fast forward speed | 0.01-125mm/s |

| Minimum speed can be set | 0.01mm/s |

| compress time | 0-99s |

| equipment power | 5KW |

| Supply voltage | 3~AC380V 50HZ |

| Weight approx. | 550kg |

| Servo motor and reducer connection method | direct way |

|

|

Dimensional drawing

Main system configuration

| num | Main components |

| 1 | Programmable control panel |

| 2 | Industrial touch screen |

| 3 | Pressure Sensor |

| 4 | server system |

| 5 | Servo cylinder |

| 6 | Safety grating |

| 7 | switching power supply |

| 8 | Haoteng industrial computer |

| 9 | Displacement grating ruler closed loop |

(Introduction to control system structure diagram)

System software main interface

Management: Contains jump interface program backup, shutdown, and login method selection.

Settings: Contains jump interface units and system settings.

Reset to zero: clear the load indication data.

View: Language settings and graphical interface selection.

Help: version information, maintenance cycle settings.

Pressing plan: edit the pressing method.

Redo a batch: Clear the current pressing data.

Export data: Export the original data of the current pressing data.

Online: The board establishes communication with the program.

Force: Real-time force monitoring.

Displacement: real-time press stop position.

Maximum force: The maximum force generated during the current pressing process.

Manual control: automatic continuous descent and rise, inching rise and fall; test initial pressure.

Main system operations:

1. After selecting the product model on the main interface, there is a product model, and you can edit and add the corresponding content independently.

2. Operator information interface: You can enter the operator information of this station: work number

3.Parts information interface:

Enter the part name, code, and batch number of the assembly in this process

4. Displacement uses a grating ruler for signal collection:

Position control mode: precise control accuracy ±0.01mm

Force control mode: precise control of output with 5‰ error

5. The system saves and uploads information:

It is necessary to upload process parameters such as workers, parts information, parameter settings, and press installation process monitoring data. The upload interface is RS485 or Ethernet TCP/IP.

communication method

1. Serial port RS232 communication (fixed to COM1)

Baud rate: 9600/19200/115200, etc. can be set (fixed one rate, 19200 is recommended)

Verification method: none

Data bits: 8

Stop bit: 1

2.PLC sends: slave address + function code +CrLf

Electric cylinder controller replies: slave address + (function code + 1) + Data + CrLf

Since RS232 communication is used, the slave address is fixed at 16#01

Example: PLC sends data frame: 01 02 xx 0d 0a //where xx represents process parameters (0-255)

The controller feedback is as follows: (byte, 6byte in total)

01 02

xx //Current process parameters

xx //0 means success, 1 means failure

0d 0a

6. The device has a code scanning function: Identify parts barcodes or QR codes and store them in the data system

7. Perform statistical analysis on data such as: defective product rate, process capability index, etc.

8. The input and output interfaces are available for backup, and the interface is open for users to perform simple programming.

9. Equipped with calibration device for force and displacement sensors

10. Functions of segmented pressure: The procedure is divided into 20 times or less

Equipment characteristics

1. The equipment has high precision: repeated displacement accuracy ±0.01mm, pressure accuracy 0.5%F.S.

2. Energy saving and environmental protection: Compared with traditional pneumatic presses and hydraulic presses, the energy saving effect reaches more than 80%, and it is more environmentally friendly and safe, and can meet the requirements for dust-free workshop equipment.

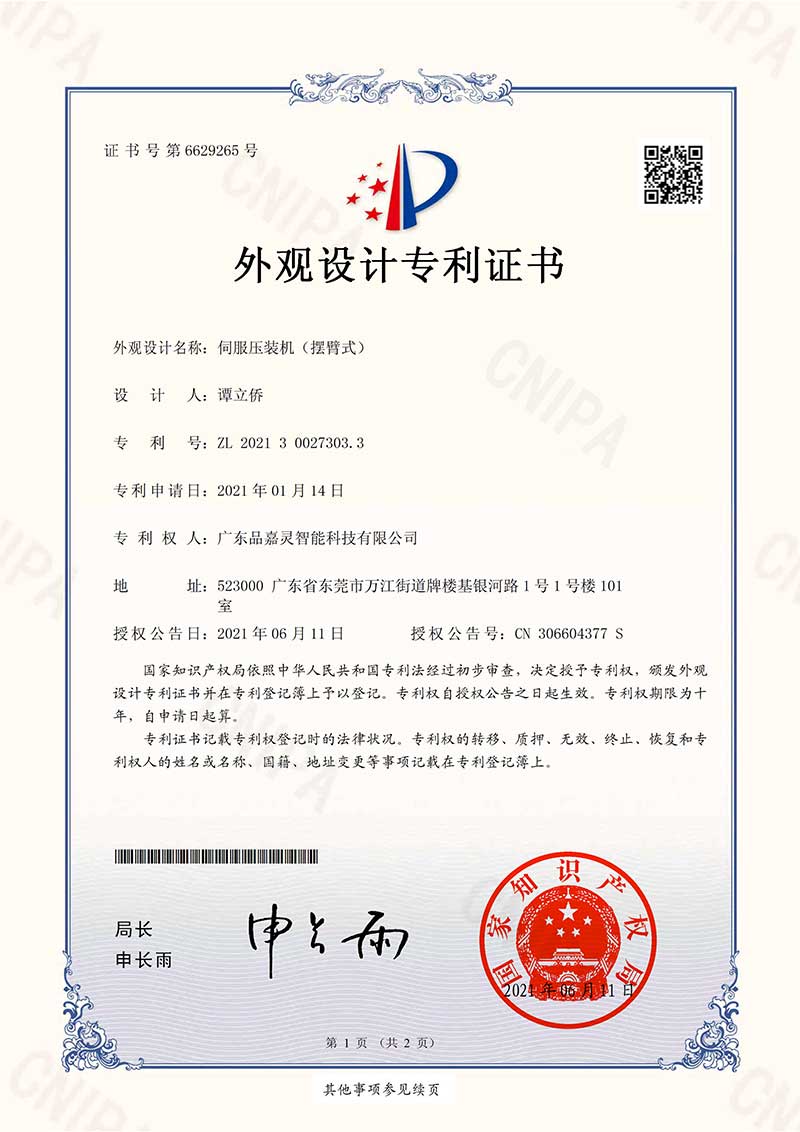

3. The software is independently patented and easy to upgrade and maintain.

4. Various pressing modes: optional pressure control, position control, and multi-stage control.

5. The software collects, analyzes, records and saves pressing data in real time, with a data collection frequency of up to 1000 times/second. The control motherboard of the press installation system is connected to the computer host, making data storage and uploading faster and more convenient. It enables product press installation data to be traced and meets the requirements of ISO9001, TS16949 and other standards.

6. The software has an envelope function, and the product load range or displacement range can be set according to requirements. If the real-time data is not within the range, the device will automatically alarm and identify defective products 100% in real time to achieve online quality control.

7. The equipment is configured with a computer host and Windows operating system. The operating interface language of the press installation control system can be freely switched between Chinese and English.

8. The equipment is equipped with a 12-inch touch screen to provide friendly human-machine dialogue.

9. The equipment is equipped with a safety grating to ensure the safety of operators.

10. Achieve precise displacement and pressure control without the need for hard limits and reliance on precision tooling.

11. Specify the optimal press-fitting process according to specific product requirements.

12. Specific, complete and accurate operation process recording and analysis functions. (Curves have functions such as amplification and traversal)

13. One machine can be used for multiple purposes, flexible wiring and remote device management.

14. Export multiple data formats, EXCEL, WORD, data can be easily imported into SPC and other data analysis systems.

15. Self-diagnosis function: When the equipment fails, the servo press can display an error message and prompt a solution, making it easy to quickly find and solve the problem.

16. Multi-function I/O communication interface: This interface can communicate with external devices to facilitate fully automated integration.

17. The software sets multiple permission setting functions, such as administrator, operator and other permissions.

Application fields

• Precision press-fitting of automobile engines, transmission shafts, steering gears and other parts

• Precision press mounting of electronic products

• Precision pressing of core components of imaging technology

• Motor bearing precision press fitting application

• Precision pressure testing such as spring performance testing

• Automated assembly line applications

• Press assembly application of aerospace core components

• Medical and power tool assembly

• Other occasions requiring precision pressure assembly

We have obtained various international management system certifications and comply with production standards in different regions.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- What is the maintenance required for a servo press machine?

- What safety precautions should I follow when operating a servo press machine?

- What is a Desktop Servo Riveting Machine?

- What are the advantages of servo presses in forging?

- Is there any warranty after purchasing the servo press?